Zote foam (aka: cross-linked polyethylene) is a semi ridgid, rubber like, durable foam that can be heat formed to fairly complex shapes. It has several advantages over other various shell construction methods.

Zote vs Composite shell

1. Much lighter

2. Much cheaper

3. Much quieter

4. Doesn't slide as far. Takes crashes much better(no lost paint, composite layers) only scuffs a bit.

5. Not quite as fast above 30mph due to shell wind deflection and rougher surface texture. This may be fixable, we'll see.

Other shell options would be thin sheet aluminum, which has similar performance to composite

including crash characteristics.

Coroplast, which is quite durable and cheap, but doesn't conform to complex shapes, and isn't all that light or cheap compared to Zote.

Or Dacron cloth, which shares Zote's characteristics except for the fact that it is harder to create complex shapes with, doesn't offer much crash protection, and isn't all that durable.

I may play with a Dacron/Zote mix shell design later.

Zote is a very rider friendly shell material. Light for climbing hills, fast enough for most race events, and cheap/durable enough to commute in.

This is the molding stand for the Varna. Zote foam will be draped over the top of it, pulled down by the bungees, and carefully heated to shape by radiant heaters.

This is the molding stand for the Varna. Zote foam will be draped over the top of it, pulled down by the bungees, and carefully heated to shape by radiant heaters.

I ended up having to guy my pulley system off of the end poles of the building, as the hanging weight of the heaters was twisting my rafters more than I was comfortable with. I built the pulley system about 15' long to accomodate longer projects I have in the works. I still need to finish the cross cables so that when you pull one side of the trolley the other side will follow without twisting. Should have that finished up midweek.

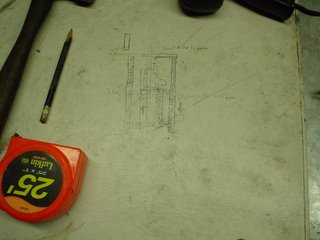

This is the sketch of the Zote foam welder, a blatant copy of John Tetz's. John is the Zote foam master, all of what I know about foamshells has come from him. We also have a set of shell molds that will be used later from John. Thank you John. You can check his projects out at http://www.recumbents.com/mars/

This is the sketch of the Zote foam welder, a blatant copy of John Tetz's. John is the Zote foam master, all of what I know about foamshells has come from him. We also have a set of shell molds that will be used later from John. Thank you John. You can check his projects out at http://www.recumbents.com/mars/

The welder is nothing more than a soldering gun with a flattened tip (so as not to leave bulges in the foam) that melts the foam together. I need to fill the gap in the blade as it still tends to catch a little.

The welder is nothing more than a soldering gun with a flattened tip (so as not to leave bulges in the foam) that melts the foam together. I need to fill the gap in the blade as it still tends to catch a little.

The table and mechanism is necessary to keep from bending the thin blade over, to keep from melting things you don't want melted, and to aid in the welding process. In order to weld two peices together, you step on the petal(which raises the blade and turns on the gun) and push two peices of foam across the blade while holding them together. Takes a little practice to get a nice seam, but when done correctly, creates a very strong bond. This is pretty important since pretty much no adhesive seems to work on the stuff.

The table and mechanism is necessary to keep from bending the thin blade over, to keep from melting things you don't want melted, and to aid in the welding process. In order to weld two peices together, you step on the petal(which raises the blade and turns on the gun) and push two peices of foam across the blade while holding them together. Takes a little practice to get a nice seam, but when done correctly, creates a very strong bond. This is pretty important since pretty much no adhesive seems to work on the stuff.

Well, back to work. And training. Gotta have an engine for this HPV, right?

5 comments:

wow...that's some cool schtuff

that's way crazy technical....

I made a birdhouse and a pop can lamp

webster's dictionary entry

bike-nerdery: http://nonconformcycling.blogspot.com/

*note: this is intended as a compliment of the highest regard.*

I don't know about driving that big yellow thing. It's kind of crowded in the cockpit.

Post a Comment